SCHLEBACH HPM

Profiling machine HPM

Robust and compact machine to produce hem seams on flues, for water folds, verges, etc. from sheet material

- Considerable reduction of working hours to edge the sheet metal

- Continuously adjustable infeed width from 130 - 870 mm (1.050 mm)

- Fold-over length 6 - 15 mm

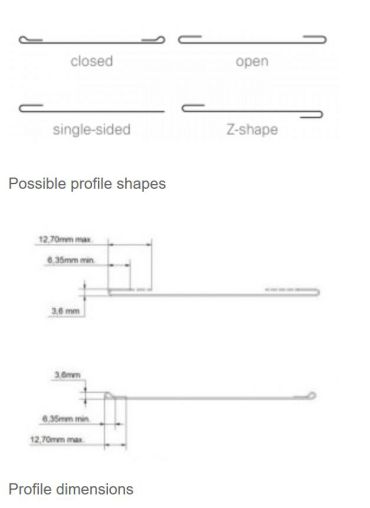

- Closed and open fold-over possible

- Z-shape with two runs

- Hem seam rotated by 180° as a special variant

- Shortest panel length 800 mm (depending on the material)

- Working speed 18 m/min

- Tapered, conical or fitting panels in 2 work cycles

- Adjustable infeed guides on ball-beraings for guiding the material

- Profile rollers made from high-quality special steel with high level of corrosion and wear protection

- Resilient mounts of the upper profile rollers ensure impression-free and low-wear production of the panels

Technical specifications

- Supply voltage: 230 V / 50 Hz / 1 Ph.

- Drive power: 1.1 kW

- Infeed width: 130 - 870 mm

- Infeed height: 890 mm

- Length of the shortest panel: 800 mm

- Working speed: 18 m/min

- Forming stages: 7 stations

- Processable materials: Titanium zinc up to 0.8 mm, Copper up to 0.8 mm, Aluminium up to 0.8 mm, Sheet steel (galvanized and coated) up to 0.7 mm, Stainless steel up to 0.5 mm

- Dimensions (L x W x H): 1,860 mm x 1,510 mm x 1,160 mm

- Weight: 450 kg