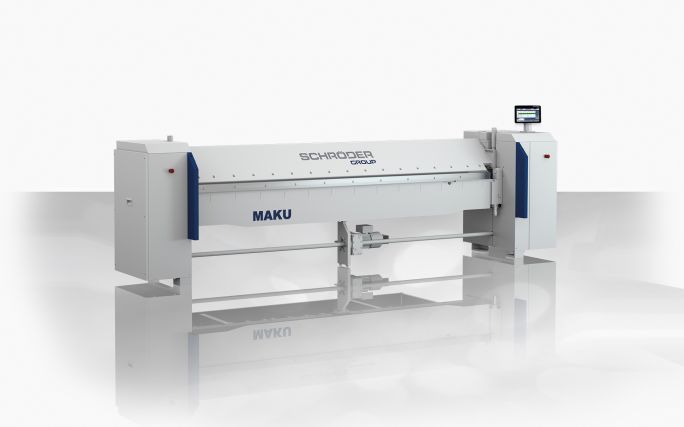

SCHROEDER MAKU

The motorized folding machine MAKU is the ideal entry into motorized thin sheet metal processing for up to 2.5 mm thick sheet metal.

For plumbers and repair workshops.

This type of machine represents a versatile solution – the U in its name stands for „universal“.

No other machine on the market offers so many clearances. It is the first machine in the world with a two-axis back gauge for automatic conical bending.

Details standard configuration:

Software control

- New Classic Bend with touchscreen turnable on switch cabinet

- Radius function

Clamping beam

- 45° clamping beam with clearance 65 mm on the rear

- Drive: middle motor 0.75 kW

- Clamping beam stroke: 150 mm

- Clamping pressure adjustment via handwheel (without tools)

- Clamping beam tools: Tinsmith blade or optionally sharp nose blade 20°, ca. 700 N/mm², directly screwed to clamping beam

Folding beam

- Drive: 1.5 kW (converter-controlled)

- Manual adjustment: 30 mm

- Folding blades 10 mm and 25 mm (from MAKU 3200: 15 mm and 25 mm); 700 N/mm²

Bottom beam

- 45° bottom beam with clearance 54 mm on the rear

- Bottom beam blade, one-piece, 8 mm lowered, ca. 700 N/mm², from 30 mm: 8 mm lowered, depending on chosen gauge

- without finger grooves

- with finger grooves 6 mm or optionally 10 mm

Others

- Foot switch

- Anchor plates incl. dowels

Software:

nanoTouch

The most clearly laid-out alphanumeric control

A software invention from Schröder Group and perfect for workshop

and factory application: nano Touch is a modern alphanumeric control that

serves as an optional software for the folding machine MAKU.

“nano Touch”controls the clamping beam and the folding beam using a path measurement

system, and the motorized back stop is controlled via the digitally controlled

frequency inverter. The user interface is clearly laid-out and combines

easy-to-understand icons with text and numerical displays.

POS 2000 Professional

The standard for industrial folding machines

The proven POS 2000 Professional makes programming a folding machine fast

and comfortable. The desired program components can be selected from a

comprehensive and expandable catalog, the angle and side dimensions are easily

changed by pressing the monitor.

The control software displays exactly what the machine is doing: The

folding machine, work piece, and tool are displayed schematically and updated

for every bending step. Anyone who programs preparation of the work away from the

machine can test the quality of their program using the bending simulation,

which effectively avoids waste and delays during production.

The software not only controls the machine, but also offers assistance to the user:

all of the necessary operator activities like turning, rotating, etc. are

displayed for each bending step.

Technical Data:

|

TYPE |

SHEET THICKNESS | WORKING LENGTH | CLAMPING BEAM STROKE | FOLDING BEAM ADJUSTMENT | CLAMPING BEAM DRIVE | FOLDING BEAM DRIVE |

| (mm) | (mm) | (mm) | (mm) | (kW) | (kW) | |

| 2000 x 2.5 | 2.5 | 2020 | 150 | 30 | 0.75 | 1.5 |

| 2500 x 2.0 | 2.0 | 2520 | 150 | 30 | 0.75 | 1.5 |

| 3200 x 1.5 | 1.5 | 3220 | 150 | 30 | 0.75 | 1.5 |